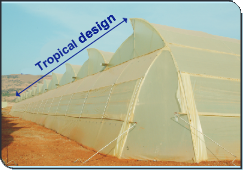

Polyhouse - Natural Ventilated Greenhouse with 10% Top Ventilation

Features of this structure

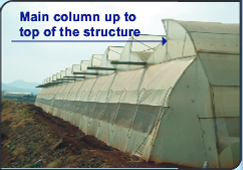

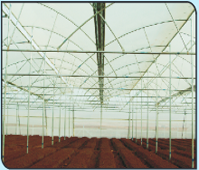

1. Tropical Design : Column runs up to top of the Greenhouse to ensure maximum strength to the structure.

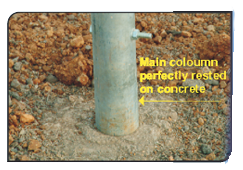

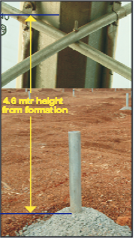

2. Anchoring Foundation Coloumn: Formation level of Greenhouse are perfectly maintained in concrete ensures resting of main column on concrete.

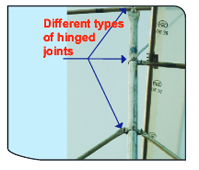

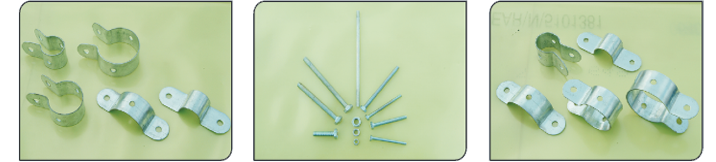

3. G.I. Pipes structure with Hinge Joint: G.I. Pipe members are joined to each others by means of clamps, angle brackets & nut bolts which ensures more strength against the vibrations caused by wind.

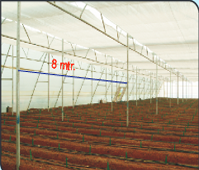

4. 8 mtr. X 4 mtr. Structure Grid : Multispan structure having 8 mtr. truss span and 4 mtr. distance between two trusses.

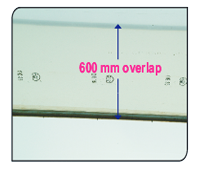

5. 10% Top Ventilation : 800 mm clear opening placed at top to ensure better ventilation and 600 mm overlap to avoid direct entry of sunlight into Greenhouse.

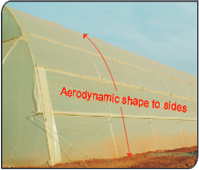

6. Aerodynamic Shape along Periphery : This shape is given to drift away wind flow and minimize the wind impact on the sides of Greenhouse to ensure maximum strength of structure against wind.

7. 4.6 mtr. Gutter Height : This height is from foundation formation Level to bottom of Gutter . Total height of the structure is 6.5 mtr.

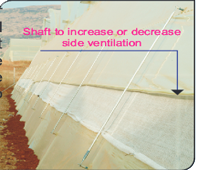

8. Curtain opening along periphery : This system allows to minimize or maximize side ventilation as per the requirement and ensures outside cold air to flow inside and push inside hot air to outside from top ventilation. Also by closing side ventilation one can block Co2 exhausted by plant inside the Greenhouse during night & use the same in morning to increase photosynthesis of the plant.

9. Curtain Flap Controls : Avoids the outside flapping of polythene curtain ensures more life of the side polythene.

Technical Excellency of IGPL

Foundations : Foundations are aligned by theodolite and dumpy level. Level of concrete are maintained as per the slope required resulting proper resting of main column on the concrete.

Bottom Chords : Straightness of the bottom chord is maintained for any length of the Greenhouse by means of perfect mathematical calculations, resulting more strength & good aesthetical appearance to the structure.

Ideal selection of Radius for Top Arches : IGPL has selected optimum radius for top chords which results in to less wind pressure through vents and avoid lifting of top polythene and also reduces wind pressure due to aerodynamic design.

Flap Control & Curtain Runners : IGPL provides flap control pipe that avoids the flapping of curtain paper & reduces maintenance due to wind pressure. Extra purlin is provided along periphery with aluminum gripper which increases strength of structure and also increases life of side polythene.

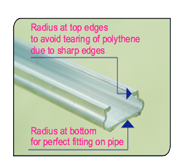

Aluminum Gripper : Curvature at the bottom surface for perfect fitting on the pipes and radius is given to the edges where polythene under stress.

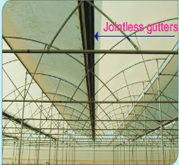

Gutter : Trapezoidal shaped gutter in single piece made from G.P. sheet coil and are placed on the structure by means of modern technology.

Fixtures : Clamps are made from hot galvanized sheet, hot galvanized nuts & bolts are used for connection of the

Corridors : Bended / Hockey stick type corridors are used along width of the Greenhouse. Straight corridors are used along length of Greenhouse to stop displacement of main column from heavy wind resulting more strength to structure.

IGPL erects the structure by its own developed technology and not by conventional method using scaffolding etc. No pressure / pre-stress remains in the member after erection. Experienced team of engineers from SGPL selects the orientation of the Greenhouse by studying the local topography & Metrology.